Seamless Precast Terrazzo Transformation: A Pinnacle Stone Restoration Project at 212 Kimberly Road

Making Precast Terrazzo Seamless

Welcome to 212 Kimberly Road—an architectural gem nestled in North Barrington, Illinois. Designed in 1949 by Don Tosi, a protégé of Bruce Goff, this mid-century modern home reflects a rare fusion of geometry, space, and artistry. At Pinnacle Stone Restoration, we were invited to complete a unique challenge: transform a brand-new installation of precast terrazzo tiles into a seamless, poured-look terrazzo floor.

This detailed case study demonstrates how we used our terrazzo floor refinishing system to overcome the limitations of precast terrazzo and achieve a seamless finish, preserving both the architectural vision and the material’s natural character. This story is for architects, interior designers, and restoration professionals who want to understand how diamond honing and terrazzo polishing can elevate a surface from segmented to spectacular.

Understanding Precast Terrazzo in Modern Design

Precast terrazzo is fabricated in panels and installed like tile, often chosen for its practicality and factory precision. However, it inherently lacks the monolithic visual effect of poured-in-place terrazzo. Visible joints, grout lines, and reflectivity inconsistencies can break the visual flow.

The terrazzo tiles at 212 Kimberly Road were newly installed, but the homeowner and architect both wanted a seamless terrazzo look—something clean, elegant, and free of visual interruptions. Our job was to refinish precast terrazzo to match that vision without replacing the floor.

Our Step-by-Step Seamless Terrazzo Refinishing System

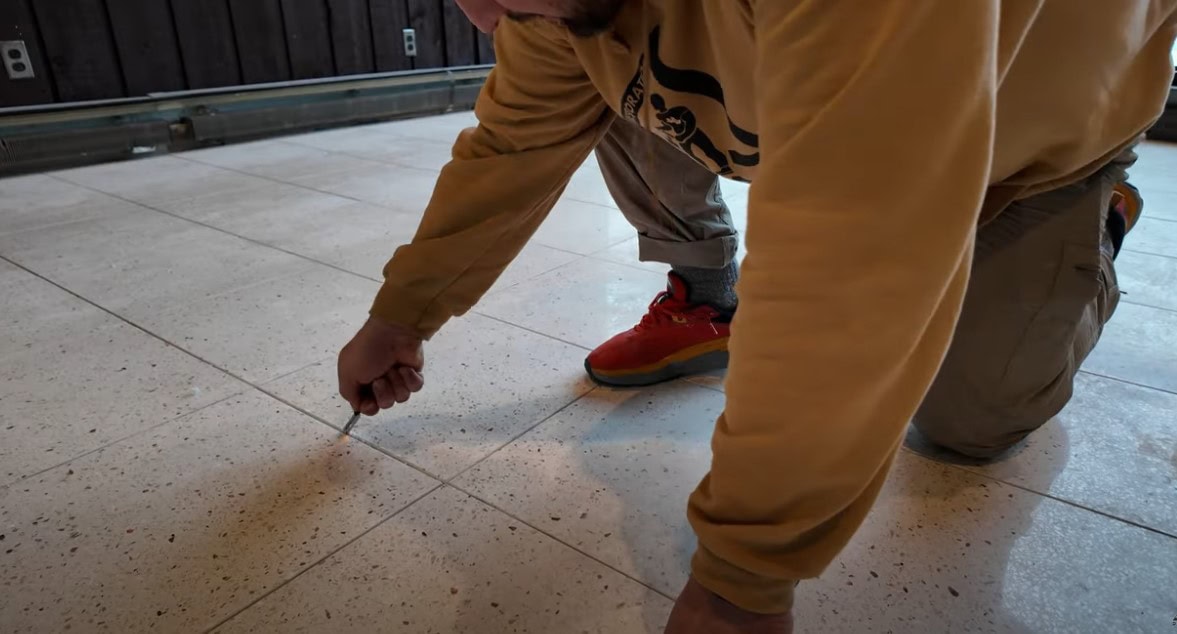

Step 1: Cleaning All Grout Joints

We manually cleaned every grout joint with handheld scrapers, removing thinset and debris. A clean joint is essential for proper adhesion and visual blending during resin work.

Step 2: Color-Matched Resin Joint Filling

Using a custom-made, color-matching resin, we filled each joint to perfectly match the terrazzo matrix. Overfilled slightly, the resin was left to cure overnight to prepare for leveling.

Step 3: Diamond Grinding Using Metal-Bond Pads

We began the heavy grinding phase using Hyper Grinder machines with metal-bond diamond tools. This aggressive grind flattened the entire surface, removed excess resin, and eliminated lippage between panels.

Step 4: Seamless Edge Work

Edges and perimeters were treated with the same care as the field. Flatness and finish had to be consistent throughout the space.

Step 5: Pinhole and Microvoid Filling

During grinding, micro imperfections became visible. We used flashlights to locate and fill each flaw with detail, creating a flawless surface before honing.

Step 6: Multi-Stage Diamond Honing

We progressed through 200, 400, 800, 1500, and 3500 grit resin-bond diamond pads, tightening the surface and building clarity. This process is 100% mechanical—no sealers, no topical coatings.

Step 7: Leveraging the Density of Precast Terrazzo

Unlike traditional terrazzo, precast terrazzo is manufactured under high compression, similar to quartz countertops. That density allows it to take a sharper polish and produce a glass-like reflection.

Step 8: Specialized Terrazzo Polishing Paste

We polished the surface with a marble polishing compound made specifically for terrazzo, enhancing its brilliance while preserving its stone-like texture.

Step 9: Penetrating Sealer Application

Our water-dispersed penetrating sealer was applied using a floor machine. It evenly protected the floor without creating artificial shine, allowing the material’s clarity to speak for itself.

The Final Result: Poured-Look Terrazzo from Precast

The floor was transformed into a seamless terrazzo slab. Panel joints became invisible. The surface reflected light uniformly. The original vision of a continuous terrazzo floor in a mid-century modern home was fully realized.

Why Architects and Designers Should Consider This System

This project is a bold example of what’s possible with precast terrazzo refinishing. With the right approach, you can:

- Achieve a seamless look from modular precast panels

- Avoid expensive demolition and replacement

- Preserve architectural intent with technical accuracy

If you’re an architect or designer specifying terrazzo in residential or boutique commercial spaces, know that the limitations of precast are solvable with the right refinishing partner.

Watch the Full Process

We documented the entire terrazzo transformation on video:

Partner with Pinnacle Stone Restoration

At Pinnacle, we specialize in bridging the gap between concept and craftsmanship. Whether you’re designing a luxury residence, gallery, or historic property, we deliver seamless terrazzo and stone surfaces that elevate your design.

Want to discuss your project? Contact us at pinnaclestonerestoration.com.

Pinnacle Stone Restoration

Where material meets mastery. Where surfaces become statements.