70-year-old terrazzo floor polishing and altar marble floor restoration and repair at Catholic Church in Chicago suburbs – honing, densifying, polishing, edges, vitrification, sealing, burnishing, repair.

70-year-old terrazzo floor polishing and altar marble floor restoration and repair at Catholic Church in Chicago suburbs – honing densifying polishing edges vitrification sealing burnishing repair

This 70+ year old cement-based terrazzo floor has never been refinished. Our task is to restore it and bring the original high sheen back.

This terrazzo floor was in a pretty bad shape with lots of cracks, holes, scratches, and a significant amount of wax that accumulated over the years.

Our friend company has taken care of all the terrazzo patching, repairs and the first level of grinding terrazzo.

Terrazzo Grinding and Densification process

We start with 200 grit mechanical diamond grinding of this terrazzo floor.

Next step we take care of densifying terrazzo. Densification increases terrazzo density and makes it tenacious so it can withstand abrasion a lot better and wear less.

After densification process is complete, we continue grinding terrazzo with 400 level diamond grit.

Terrazzo Polishing

We continue polishing terrazzo with 800, and 1500 diamond grit level.

At this point terrazzo is getting a high gloss from a mechanical diamond polishing.

We finish our polishing part of the process with 3000 grit.

Terrazzo Edges Polishing

We work on edges with a special edge machine to ensure we can reach all the corners and hardly reachable places for the floor machines.

We finish with the micro topping sealing of terrazzo to help protect the surface from staining and friction. There will be a lot of people coming to this church on the weekends and our priority is not only to make this terrazzo floor look gorgeous again but also be safe for all the people who come in.

Vitrification of terrazzo floor

We use the final polishing process that is called vitrification. From French is has a meaning “to make it glass like” surface. Therefore, we want to make a surface to look glass-like. It is a different process of that what is called crystallization process.

Vitrification of this terrazzo would change the floor’s chemical composition of the surface to a pretty hard high gloss sheen.

The final touch of this restoration process is terrazzo sealing and burnishing. We made the floor beautiful, safe and slip resistant.

FINAL RESULTS

BEFORE AND AFTER

MARBLE ALTAR FLOOR RESTORATION AND REPAIR

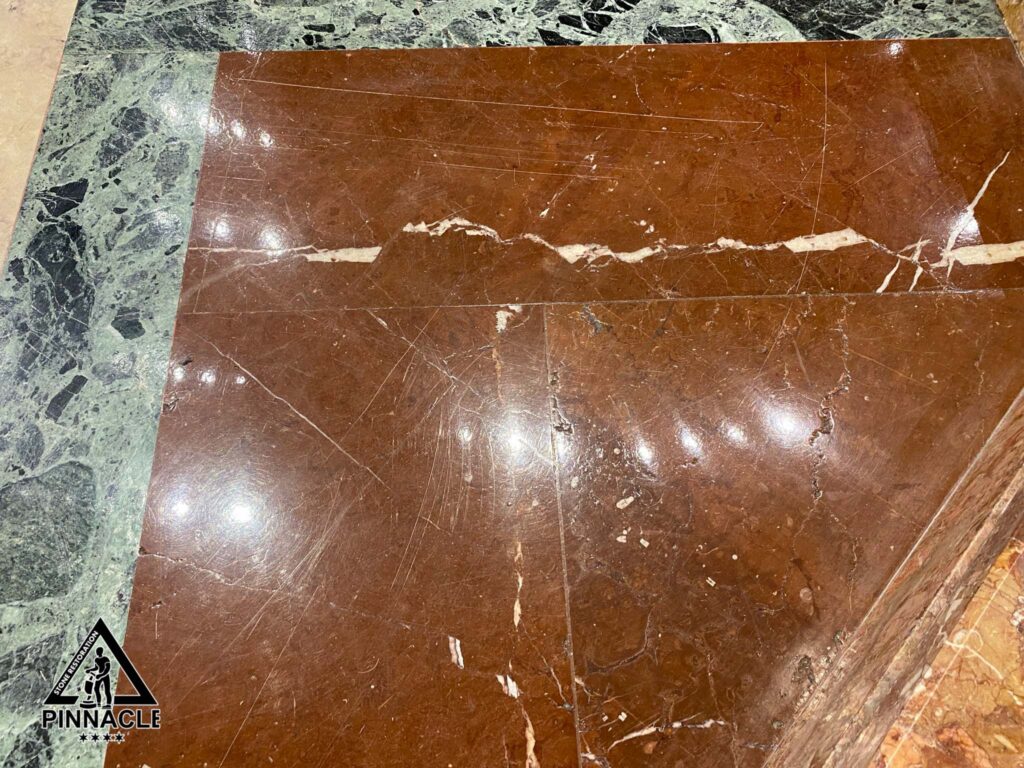

Before

When we finished terrazzo floor restoration part of the project in this church the second part that was left is the marble altar floor and stairs.

Just like terrazzo the marble floor was heavily waxed throughout the years and has never been mechanically refinished before.

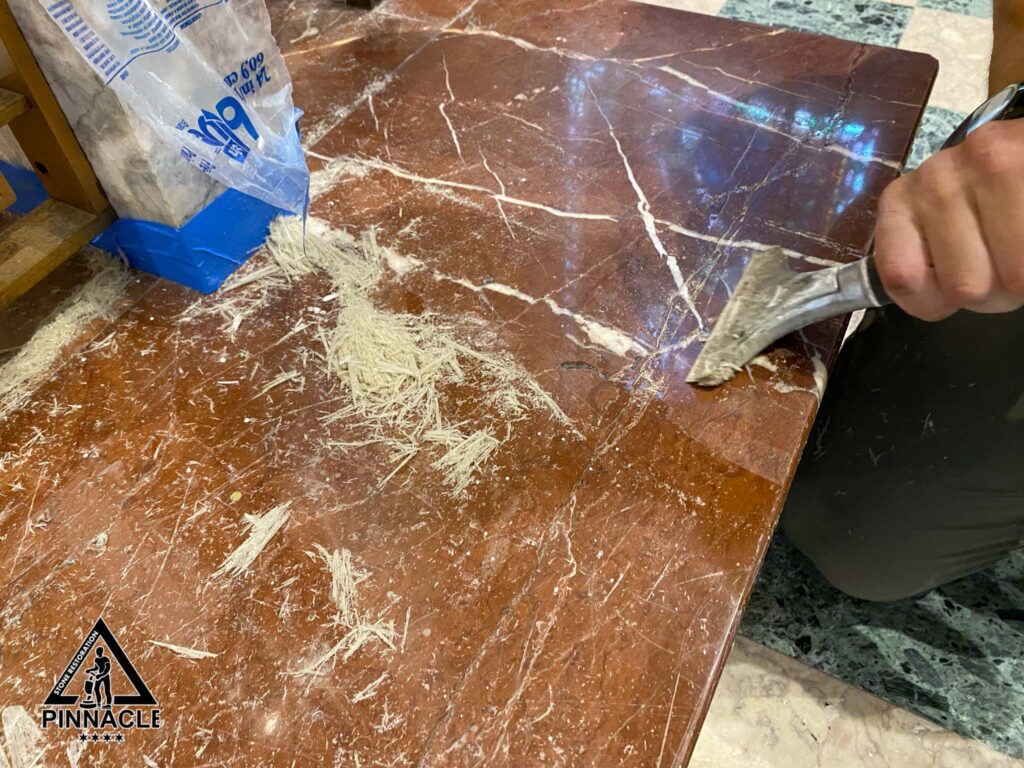

Marble Wax Stripping

First step is for us is to perform wax stripping process. We use floor machine for the overall surface wax stripping and also do wax stripping by hand on edges, corners, and stairs for a thorough reach everywhere.

All the beauty of this natural stone was hidden under the thick layer of wax.

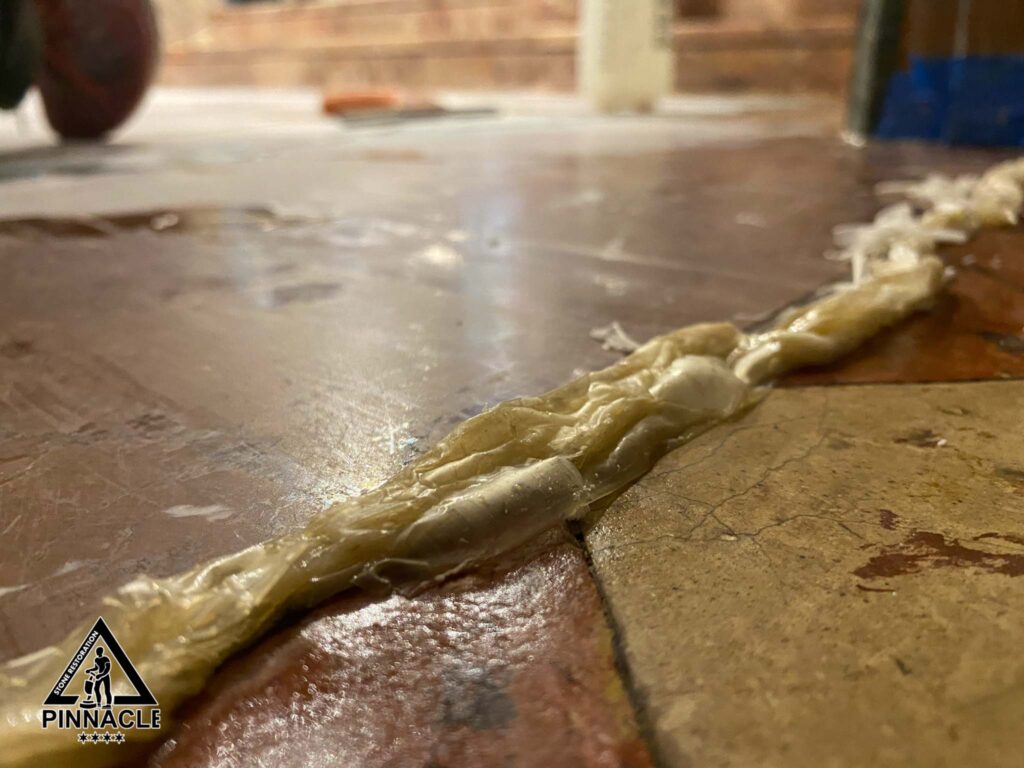

Marble Floor and Steps Crack Repair

Marble steps and other places on the floor had vast number of large cracks and holes that needed repair.

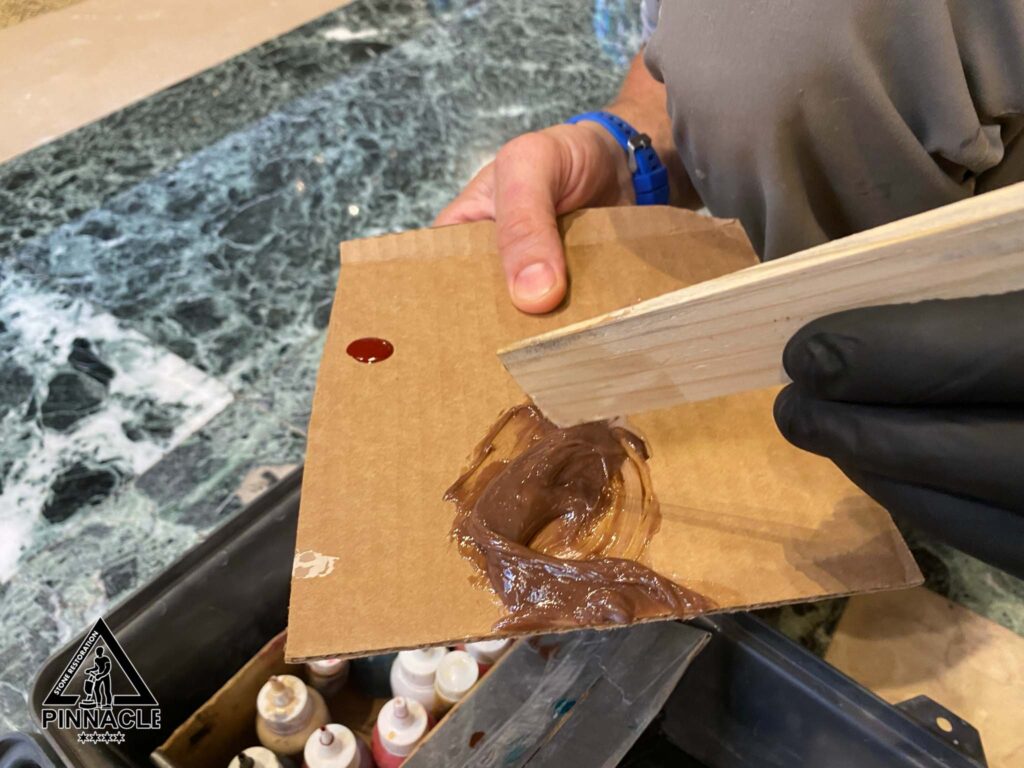

We color match the epoxy filler with the marble and fill the cracks and holes. After it cures we grind the excess of epoxy filler and then polish marble surface with the same steps as the rest of the marble floor.

Grinding marble tiles

Some parts of the altar floor had marble tiles that needed leveling. We started the grinding process with our heavy-duty pads on our floor machines so we could ensure the lippage removal of those tiles and a smoothness of the floor.

We continue with 100, 200 and then 400 grit level diamond pads.

Polishing Marble floor

Next up in our polishing process is 800 grit level diamond pads. At this point we begin to see the sheen of the surface.

Following with 1500 and 3000 level grit of our D.I.P. System (Diamond Impregnated Pads).

We work on all the edges and the stairs with our hand help machines.

We end our polishing process the same way we did with terrazzo at this church. We use vitrification system to have the surface look like a grass finish one.

Marble sealing is, as always, a vital part of the restoration process to be finished with. The surface is now restored and protected and can last for many more years and generations ahead.