Diamond Brushing Or Antiquing Granite Floors

Did you know that besides polishing or honing granite or most of the natural stone surfaces you can also antique finish them?

It also called brushed finish or leather finish. The idea behind is to create a textured surface on a face of stone that would mimic wrinkled and grooved leather sheet.

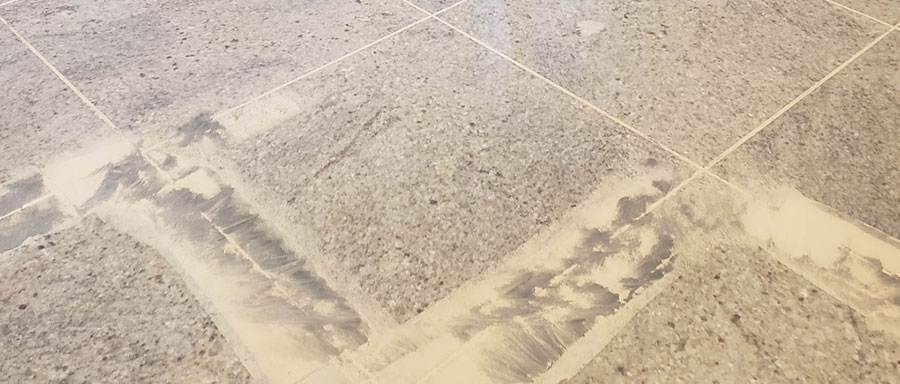

A not that long ago we came across to old granite floor with regular wear and tear, existing lippage, loose and dirty grout, and severe staining. It had to be restored and refinished.

When it comes to granite refinishing there are no shortcuts to be taken. It always requires deep grinding and lippage removal for the absolute flatness of the surface, therefore diamond pads full contact is achieved on every part of the working surface.

The first challenging phase of the process is to explain the customer the options if there are any. In this particular project, there were a few options that could be executed with a successful outcome.

The first traditional course of action would have been diamond refinishing and polishing or honing. ( Not very effective )

The second would include everything above plus grout replacement and lippage removal. ( Very effective )

The third and the most interesting option for this specific floor was diamond brushing with grout replacement and unavoidable lippage removal.

The customer was convinced to go with the third option. A decision was based on the expectation of making existing granite floor appearance unique and modern.

The process started with the lippage removal step. The floor needs to be cut with an aggressive metal bond diamond system to ensure the total flatness of the surface. For that reason, we had to use a planetary head grinding machine to ensure an effective cutting process and rate.

The lippage removal was followed by a grout removal step. This process requires steady hands and a skilled technician. Without damaging granite tiles with diamond blades, existing grout is detached and the same time disposed of with a dry vacuum.

Cleaned and prepped grout joints need to be filled with knife grade epoxy mastic. The goal is to exaggerate the filling process due to shrinking habits of epoxy resin during the curing period.

After the epoxy resin is cured and hardened it is time to remove excess material by grinding it with a medium grit metal bond diamond disc system. It is a time-consuming process that requires evenly distributed and patterned grinding techniques.

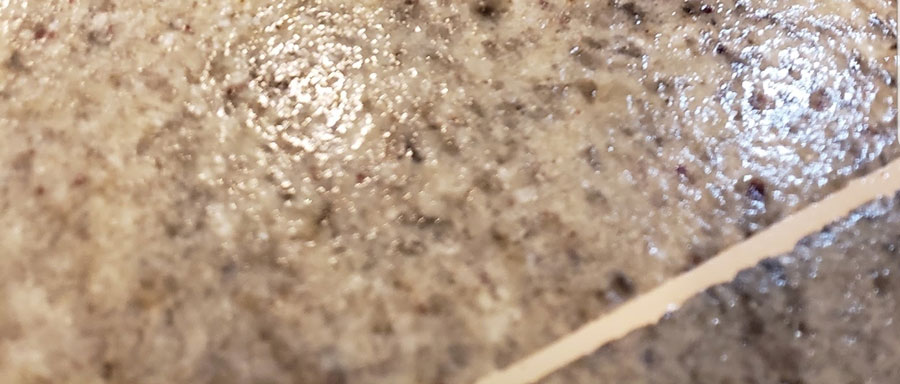

Time for diamond brushing. For this step carefully selected diamond grit brushes are selected. It is recommended to start with the most aggressive grits to produce a textured profile on the stone. Consistent agitation of the granite surface with aggressive diamond brushes creates deep grooves into the surface which eventually develops as a textured profile.

The Brushing process includes various grits of diamond brush sets. From low grit to medium and fine as a final step. The edgework needs to be done with handheld grinders with the same order of methodology as the main floor.

Each stage of the refinishing process requires accuracy and patience. In the middle of the refinishing stage, the floor has already developed its characteristics. Leather finish texture was getting significantly pronounced with every step of the way. The last and finest grits of diamond brushes have created smoothness and necessary luster to accent leather texture that was successfully shaped.

The sealing process was done with a water-based impregnating sealer using a microfiber pad as a distributing tool.

All the components thoroughly came together. A combination of lippage free floor, epoxy grout, leathered texture, and sealer have put behind the previous appearance and modern look took over with above satisfactory rate.

I hope that this blog helps to see another dimension of stone refinishing.